Introduction

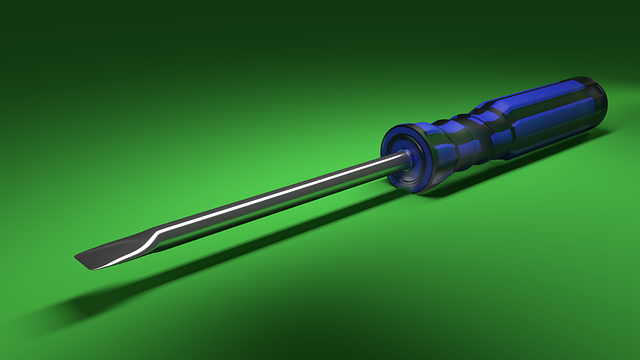

Screwdrivers are vital instruments that perform in many sectors and homes. They are great in any field, be it assembling furniture or conducting mechanical repairs. Another significant point that characterizes the work of a screwdriver is a material it is made of, and especially, a tip or blade. Ranging among a certain number of materials, steel can be taken as the most widespread and efficient one, particularly in the cases of operation with ferrous material. Why is the screwdriver made of steel especially in such applications?

This Blog discusses the science, properties and practical reasons of using steel as a ferrous material screwdriver and gives a detailed insight on the significance of using it in making tools and even its use.

Knowledge on Ferrous Materials

In order to have a complete idea of why steel is ideal to use, one should first have an idea of what are ferrous materials. Metals that have iron are called ferrous materials. Such typical ones are carbon steel, alloy steel, cast iron, and wrought iron. Such materials are characterized by strength, durability and magnetic properties.

Ferrous materials are quite hard and frequently used in an architectural setting and in machines, and as such all the tools involved in the work with them such as screwdrivers are supposed to be hard and wear resistant as well. Here is where steel and high-grade steel come in handy.

Why is Steel the Perfect Choice of Screwdrivers?

Steel is a combination of iron with a little bit of carbon and in few cases other elements such as chromium, vanadium, or molybdenum. These additions help in improving the quality of steel thus turning it to a perfect tool-making material. And this is why steel is particularly accommodating in the screwdrivers that are applied to ferrous material:

Strong and tough

The mechanical strength required to use a screw driver or to remove screws in ferrous surfaces is supplied by the steel. Structurally strong steels such as high-carbon and alloy steel may be heat treated to attain high hardness, a factor that inhibits abrasion of the screwdriver tip or its deformation during use.

Weathering and Impact resistance

Ferrous rock is either abrasive or intensely hard. A soft material screwdriver may wear out fast and in some cases break off. The wear resistance of hardened steel is incredibly high, the question is, that the shape and sharpness of screwdrivers do not change even after a long period of time and their subsequent use.

Corrosion Resistance

Not all types of steel are corrosion free, but screwdriver versions may be hardened steel containing chromium (such as stainless steel) or coated to avoid corrosion. It is particularly essential in the case of ferrous materials which are sometimes in contact with moister and other elements in the environment which encourage oxidation.

Magnetic Properties

A large number of screwdrivers manufactured out of steel are capable of being magnetized. This enables them to grip screws easily a trait that comes in handy when fixing ferrous screws or during crowded areas. Another benefit that is not typical of other tool material such as brass or plastic is the natural magnetic response of steel.

Kinds of Steel employed in Screwdrivers

All steel is not alike and there are many different types that are used in regard to the intended use of the screwdriver:

Carbon Steel

It is one of the most widespread steels in the screwdrivers. Carbon steel is relatively hard, durable and affordable. It tends to be subjected to heat treatment to increase its perfomance.

Vanadium Steel Chrome

Chrome vanadium steel is an alloy steel that tends to be less brittle and resist wear more than would an ordinary screwdriver- it is commonly found in high quality screwdrivers. It is also corrosion resistant hence a long lasting option towards professional equipment.

Stainless Steel

Stainless steel screwdrivers are not as difficult as carbon or alloy steels, but shield rust and have a good application in the areas where rust might be an issue as in a marine environment or medical arena. They might not have equal frequency of ferrous material work since they have little less hardness.

Tool Steel S2

S2 tool steels are heat-treated to have great hardness and toughness and are used in high-end and industrial grade screwdrivers. It can resist breaking at a higher torque level and thus the use in torturous application like on ferrous metal is ideal.

Heat Treatment Role

Heat treatment Screwdriver manufacturing is a process that requires critical steps in heat treating. It consists of the heating steel to a certain temperature and speedily cooling it in order to change the inner structure of the steel. This improves hardness, strength, and toughness of the steel and the screwdriver will not deform under pressure.

Screwdrivers on ferrous materials need to withstand high torque, impact and friction. The use of heat-treated steel also makes the tool quite sharp, efficient, and safe to operate on these conditions.

Accuracy and Fitting are the Issues

The next reason the screwdrivers use steel is its possibility to be made with a high level of precision. The tips of the screwdrivers should be correctly of the right shape to fit the screw heads, especially the ferrous screws, which are usually hardened and high torqued. The manufacturing process can be handled in high precision using steel to ensure that it fits snugly which minimizes chances of slippage and cam-out.

Econcone and Availability

Steel is relatively cheap and is widely found all over the world which makes it viable when it comes to manufacturing tools. Although other metals such as titanium or ceramics may have some niche advantage, they are both too expensive and scarce to make them relevant in screwdrivers, particularly in applications that involve ferrous materials.

Reliability and Safety

When applied on ferrous material, screwdrivers usually face a lot of resistance. A cracking or soft material might crack due to pressure which may cause safety issues. Steel has a balanced outline of flexibility and rigidness, and as such, the tool can easily absorb shocks without breaking; therefore, it is safe and reliable choice both to the professional tool user and the Do-It-Yourselfers.

Recyclability and Sustainability

Steel is sustainable too. Steel screwdrivers do not contribute to the environmental pollution because it can be reused without compromising its quality. This is closely in line with current needs of the environmentally friendly manufacturing processes.

Conclusion

In the process of manufacturing screwdrivers which are to be used on ferrous materials, nothing beats steel as the champion. It is the material of choice in the professional and everyday tool market because of its better mechanical characteristics, its resistance to wear and corrosion and on economic grounds. Be it the demanding work of repairing high-torque automobiles or the exacting work of assembly of electronics components, steel screwdrivers can be relied upon to be durable, reliable, and safe in any procedure that involves ferrous parts.

The material selection of a tool is not tradition alone but livelihood and performance and steel has withstood test after test that it satisfies all the requirements in screwdrivers that are employed in ferrous work.